Engineering plastic "mountain king" -- how was nylon born?

A brief history of nylon development:

In 1931, dupont's carroz developed the nylon 66, which became the first industrial engineering plastics, and was organized and produced by dupont in 1939.

In 1942, the germans developed the industrial technology of nylon -6 and used it as a fiber development.

1961: China development PA1010.

In 1972, dupont developed the industrial technology of aromatic nylon.

The birth of nylon.

At the beginning of this century, it was considered inconceivable that the corporate world would engage in gay scientific research. In 1926, steen, director of dupont, the largest industrial company in the United States, conducted basic research on the discovery of new scientific facts out of interest in basic science.

Dupont in 1927 decided to pay $250000 a year as research cost, and began to hire chemical researchers, by 1928 the dupont company headquarters is located in wilmington, establishment of basic chemical research institute, who is 32 carlo geysers (Wallace Carothers, H., 1896-1937) became head of the organic chemistry of the Dr

華萊士·卡羅瑟斯

Carrothers's idea is to make a polymer fiber that has to have a melting point that is high enough to withstand normal use, but also low enough to handle and bulk textiles. In the beginning, carrothers chose the reaction of diglycol and dicarboxylic acid to understand the relationship between the structure of organic molecules and their properties through this familiar reaction. In the experiment of condensation polymerization, the molecular weight was about 5000. In order to further improve the degree of polymerization, carothers improved high vacuum distillation unit and strictly control the ratio of reaction, the reaction was completely, in less than two years of polymer molecular weight of 10000 ~ 20000.

In 1930, carothers with polyester glycol and sebacic acid condensation produced, ROM of colleagues were taken out from the reactor melt polyester hill found an interesting phenomenon: when the molten polymer to the cloth with threads drawn like cotton candy, and the fibrous filaments can continue even after cooling stretching, stretching length can reach several times, after cold stretch fiber strength and elasticity increases greatly. This strange phenomenon has led them to anticipate that this feature may have significant application value, and that it is possible to use molten polymers to spin fibres.

However, continuing research shows that the fiber is only theoretically meaningful from polyester. Because of high polyester in under 100 ℃, the melting, especially soluble in a variety of organic solvents, but in the water were a bit stable, therefore should not be used for textile. Later, carruthers and his assistant focused on finding new materials, made from derivatives of acids and ammonia. In May 1934, chemist don kovman obtained the first superpolyamide. Two months later, chemist Wesley peterson made a polyamide made from castor oil, but the castor oil was not large enough to be used as a raw material.

Carruthers also studied this series of polyester and polyamide compounds. On 28 February 1935, polyamide 6/6 was synthesized from hexamethylene diamine and adipic acid. This kind of polyamide insoluble in common solvents, melting point is 263 ℃, higher than the commonly used ironing temperature, control of fiber has the appearance of the silk and gloss, on the structure and properties is also close to the natural silk, the wear resistance and strength more than any kind of fiber.

Then, dupont, and solved the problem of industrial raw materials production of polyamide 6/6, on December 12, 1939 to denominate is Nylon (Nylon) began to industrialized production, the first to realize industrialization of synthetic fiber varieties.

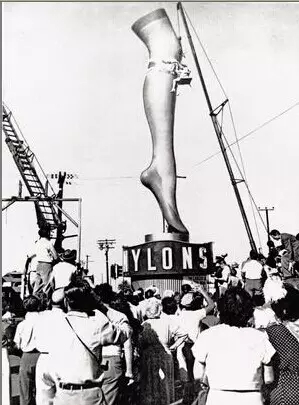

Second, nylon's maiden work - the temptation of silk stockings.

The synthesis of nylon laid the foundation of synthetic fiber industry, and the appearance of nylon changed the appearance of textiles. Nylon stockings are made with the fabric is transparent and than silk stockings durability, dupont and 10 orders, 24, 1939 in public sales headquarters caused a sensation when nylon stockings, was seen as a rare thing to snap up. People have used "as fine as silk, like steel wire is strong, like spun silk beauty" words to praise the fiber, by May 1940, sales of nylon fiber fabrics throughout the United States, then the remaining seven months time, dupont earn $3 million more, pay off the nylon the r&d budget of the project.

In 1938 dupont made nylon stockings all over the place.

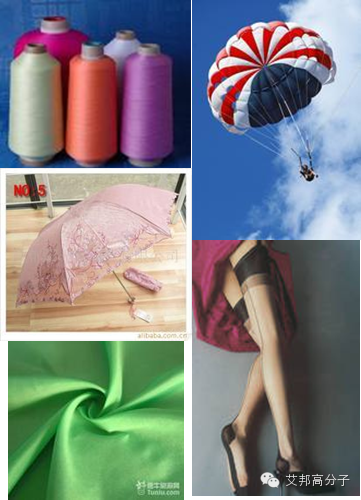

During the second world war, the nylon industry was diverted to manufacturing military products such as parachutes, aircraft tire cord fabrics, military uniforms, etc. The U.S. army bought all of the nylon products to make more than 100 kinds of military equipment.

Due to the characteristics of nylon and wide range of USES, is still very rapid development after world war ii, because the war cut off the Japanese silk products, nylon products demand even more than in 1946, from the filar socks, clothes to carpet, fishing nets, etc., nylon products appeared in countless ways.

Application of polyamide (PA) fibers.

The application of the automobile market.

Nylon is an extraordinary product created by chance. Although nylon's maiden work is fiber fabric, the word "silk stockings" has become synonymous with nylon over time. And nylon material is also found in the automobile market to have its important market position.

"Nylon is a fantastic automobile material." Dupont's Richard Mayo said in a recent telephone interview. He is the director of global business dupont performance polymers, in marketing, technology and management is composed of more than 20 years of experience, he says, nylon positioning between the resin and engineering resin, after years of development, it can deal with higher temperatures than before. Because when you increase the heat resistance of the resin glass, it also increases its strength.

Nylon was used as a molding resin in 1941. These applications include stem, wiring clamp and windshield wiper system. One of the most striking automotive applications was in 1956, when a French carmaker, Citroen, made plastic radiator fans from nylon.

Nylon has been used in various auto parts for over 50 years.

In recent years, with the development of nylon polymerization, modification and processing technology, the application of nylon material in automobile industry has become more and more extensive. Multi - variety, high performance and specialization are the key points of the application of nylon engineering plastics in automotive industry.

Current world PA and PA66 application in the automobile market possession ratio were 34% and 50% respectively, but with the increasingly stringent environmental requirements, PA resin and mixing materials continuously develop better comprehensive performance and meet the special performance of PA modified mixing material, new brands emerge in endlessly, the car is PA's largest application market, which in turn affect and promote PA modified material to high-performance, seriation and specialty direction and new type of research and development. Expected future PA applied in the car will remain high growth rates, nylon raw material factory, processing factory and end users cooperative development of high performance, easy processing, low cost, highly targeted and more environment friendly dedicated PA new mixing material to expand the application, enter the new auto parts market.

Reviewing the development history of nylon, nylon industry occupies an important position in the development of national economy and society. In the future, nylon will continue to develop rapidly in related industries and promote the high performance of engineering plastics. (source 21: plastic online, aibang polymer re-edit)